- Startpagina

- 3D Printers and accessoires

- Modelleren

- Afvormen & Gieten

- Tin Siliconen

- Platinum Siliconen

- Dragon Skin™ Serie

- Ecoflex™ Serie

- Equinox™ Serie

- Mold Star™ Serie

- Rebound™ Serie

- Smooth-Sil™ Serie

- SORTA-Clear™ Serie

- Body Double™ Siliconen

- Psycho Paint™

- PlatSil® Gel & Deadener

- Rubber Glass®

- Encapso™ K

- Solaris™

- Soma Foama™ Silicone Schuim

- EZ-Brush™ Vac Bag Siliconen

- EZ-Spray™ Siliconen

- Silicone Additieven

- PU-rubbers

- Alginaat

- PU-harsen

- PU Schuim

- Epoxies

- Polyester

- Latex, Schuimlatex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica

- Monster Makers Schuimlatex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's HX-200™ Coating/Dipping Latex

- Holden's HX-Body Latex™ - Kwastbaar

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's HX-Frisket Masking Latex™

- Holden's HX-Injection Medium™

- Latex Accessoires

- Latex Pigmenten

- Latex Verf

- Latex Thickener

- AcrylCast

- Prince August

- Gips, Gipsverband & Cement

- Jesmonite Acryl Systeem

- Buddy Rhodes Beton Systeem

- Verzegelaars & Losmiddel

- Additieven

- Pigment

- Jesmonite Pigmenten

- Pure Pigments

- Ultra Fine Pigments

- Silc Pig™ Pigmenten

- Glow Worm Pigmenten

- Cryptolyte

- Silc Pig™ Electric

- SilTone

- SilTone Kits

- Silicone Pigments - FuseFX Coloring System

- Silicone Coloring System S.A.M

- Key-Pigments Silicone Pigments

- Flock vezels

- Latex Pigments

- Polyester Pigment

- UVO Pigmenten - UV bestendig

- SO-Strong kleurstoffen

- Ignite

- Real Metal Powders

- Faux Metal Powders

- CastMagic Powders

- Verf

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint Additive

- Vallejo acryl verf

- Maker Pro Paint™ Metallics

- Vallejo Metal Color

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- Latex-verf

- Latex Paint Base

- Fuse-FX LY-series paints

- FuseFX M-series paints

- Fuse-FX F-series paint

- Jesmonite verf

- Vulmiddelen & Afwerking

- Oplosmiddelen & Verdunners

- Lijmen

- Gereedschap

- Apparatuur

- Speciale Make-Up

- Skin Illustrator Palettes

- Skin Illustrator Liquids

- Fleshstone 60ml

- Fleshstone 120ml

- Dark Fleshstone 60ml

- Dark Fleshstone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras 60ml

- Mardi Gras 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Singles

- Skin Illustrator Glazing Spray

- Skin Illustrator Glazing Gels

- Skin Illustrator Concentrates

- Skin Illustrator Mouth FX

- RipperFX Palettes

- Allied FX (Blue Bird)

- Stacolor Paletten

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- TS PAX Paints

- Rubber Mask Grease Paint

- Old Age Stipple

- Tattoo Sheets

- Kwasten Make-Up

- Stempels & Mallen

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special Effects

- Prothetische Materialen

- FormX Academy

- Toepassingen

- Literatuur

Mold Star™

Mold Star Serie (additie hardend)

Mold Star™ serie - Gebruiksvriendelijke, additiehardende, siliconen-malrubber

Mold Star™ siliconen harden uit tot zachte, sterke rubbers die scheurbestendig zijn en een zeer lage krimp op lange termijn vertonen. Mallen gemaakt met Mold Star™ gaan lang mee in je mallenverzameling en zijn goed voor het gieten van was, gips, harsen en andere materialen. Uitgehard Mold Star™ rubber is hittebestendig tot 232 °C en is geschikt voor het gieten van smeltmetaallegeringen bij lage temperatuur.

Eén op één mengverhouding — Mold Star™ rubbers worden 1A:1B per volume gemengd (geen weegschaal nodig) voor nauwkeurige metingen, zelfs bij een zeer lage massa en harden uit bij kamertemperatuur met verwaarloosbare krimp.

Geen vacuüm ontluchting — Mold Star™ siliconen hebben een relatief lage viscositeit waardoor vacuüm ontluchting optioneel is en niet vereist is voor de meeste toepassingen. Een uniforme stroom zal helpen om ingesloten lucht te minimaliseren.

Doorschijnende opties - Maak snel gesneden mallen of gietstukken Mold Star™ 19T, 20T en 31T zijn doorschijnende siliconen voor het maken van snelle mallen of het gieten in alginaatmallen. Ze bieden snelle uithardingstijden, meerdere hardheden en een oneindig aantal kleureffecten die worden bereikt door Silc Pig™ siliconenpigmenten of Cast Magic™ effectpoeders toe te voegen.

Technical bulletin Mols Star 15, 16 and 30

Technical bulletin Mols Star 20T

Mold Star 15 Slow producten

Mold Star 16 Fast producten

Mold Star 'T' producten

Mold Star 30 producten

Information

| Product naam | A:B mengverhouding | Uithardtijd | Rekbaarheid | Viscositeit | Verwerkingstijd | Shore A Hardheid | Scheurstertke | Soortelijk gewicht |

| Mold Star 15 | 1:1 by volume | 4 hours | 440% | 12500 cps | 50 min | 15 | 88 pli | 1.18 kg/lt |

| Mold Star 14 T | 1:1 by volume | 9 min | 740 % | 11,000 cps | 3 min | 14A | 90pli | 1.08 g/cc |

| Mold Star 16 | 1:1 by volume | 30 min | 440% | 12500 cps | 6 min | 16 | 88 pli | 1.18 kg/lt |

| Mold Star 19T | 1:1 by volume | 3 min | 740% | 11000 cps | 12 min | 19 | 90 pli | 1.08 kg/lt |

| Mold Star 20T | 1:1 by volume | 6 min | 740% | 11000 cps | 30 min | 20 | 90 pli | 1.08 kg/lt |

| Mold Star 30 | 1:1 by volume | 6 hours | 339% | 12500 cps | 45 min | 30 | 88 pli | 1.21 kg/lt |

| Mold Star 31T | 1:1 by volume | 5 min | 400% | 11000 cps | 23 min | 31 | 90 pli | 1.08 kg/lt |

Crystal Clear™ gieten

Instructie mal maken

Opmerking: dit product hardt niet uit tegen oppervlakken die zwavel bevatten, zelfs niet als het is verzegeld.

Veiligheid - Gebruik in een goed geventileerde ruimte. Draag een veiligheidsbril, lange mouwen en rubberen handschoenen om het risico op besmetting te minimaliseren. Draag alleen vinylhandschoenen. Latexhandschoenen remmen de uitharding van het rubber. Materiaal bewaren en gebruiken bij kamertemperatuur 23°C. Hogere temperaturen zullen de verwerkingstijd en uithardingstijd drastisch verminderen. Door materiaal bij warmere temperaturen op te slaan, wordt ook de bruikbare houdbaarheid van ongebruikt materiaal verkort. Deze producten zijn beperkt houdbaar en dienen zo snel mogelijk te worden gebruikt.

Remming van uitharding - De uitharding van het siliconenrubber kan worden geremd door bepaalde verontreinigingen in of op het te vormen patroon, wat resulteert in kleverigheid op het grensvlak van het patroon of een totaal gebrek aan uitharding door de hele mal. Latex, zwavelkleisoorten, bepaalde houtoppervlakken, nieuw gegoten polyester, epoxy of urethaanrubber kunnen remming veroorzaken. Als compatibiliteit tussen het rubber en het oppervlak een probleem is, wordt een kleinschalige test aanbevolen. Breng een kleine hoeveelheid rubber aan op een niet-kritiek gebied van het patroon. Er is remming opgetreden als het rubber gomachtig of niet uitgehard is nadat de aanbevolen uithardingstijd is verstreken. Om remming te voorkomen, is meestal een of meer coatings van een heldere acryllak aangebracht op het modeloppervlak effectief. Laat elke sealer goed drogen voordat u rubber aanbrengt.

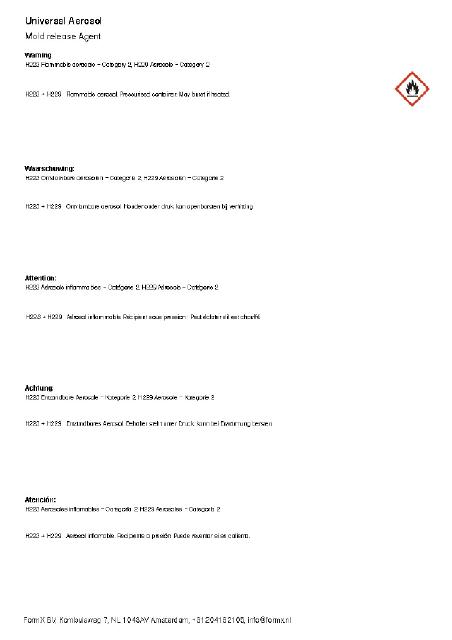

Een lossingsmiddel aanbrengen - Hoewel dit meestal niet nodig is, zal een lossingsmiddel het uit de vorm halen gemakkelijker maken bij het gieten in de meeste oppervlakken. Ease Release™ 200 is een bewezen lossingsmiddel voor het losmaken van siliconen van siliconen of andere oppervlakken. Mann Ease Release™ producten zijn verkrijgbaar vanaf formulier X

Omdat geen twee toepassingen hetzelfde zijn, wordt een kleine testtoepassing aanbevolen om de geschiktheid voor uw project te bepalen als de prestaties van dit materiaal in het geding zijn.

Meten en mengen - Voordat u begint, moet u Part A en Part B afzonderlijk voormengen. Nadat u de benodigde hoeveelheden van Onderdelen A en B in de mengbeker (1A:1B op basis van volume) hebt gedaan, mengt u grondig en zorgt u ervoor dat u de zijkanten en onderkant van de mengbeker meerdere keren schraapt. Het rubber moet een uniforme kleur hebben zonder strepen.

Optioneel... Vacuüm ontluchting - Hoewel dit niet nodig is, helpt vacuüm ontluchting om eventuele ingesloten lucht in gietbaar siliconenrubber te elimineren. Na het mengen van deel A en B, vacuüm materiaal 2-3 minuten bij 0,98 bar en zorg ervoor dat u voldoende ruimte in de container laat voor productexpansie.

Gieten - Voor de beste resultaten giet je je mengsel op één plek op het laagste punt van het insluitveld. Laat het rubber zijn eigen niveau zoeken. Een uniforme stroom zal helpen om ingesloten lucht te minimaliseren. Bij gebruik als malmateriaal dient het vloeibare rubber minimaal 1,3 cm af te vlakken boven het hoogste punt van het modeloppervlak.

Uitharden - Laat Mold Star™ 16 SLOW siliconenrubber 4 uur uitharden bij kamertemperatuur 23 °C alvorens te verwijderen.

Uitharding door warmte - De tijd om te ontvormen kan worden verkort door milde warmte toe te passen. Voorbeeld: Na het gieten van Mold Star™ 16 rubber bij kamertemperatuur, plaats de mal in een hete doos of industriële oven op 60°C. Dit verkort de ontvormtijd van een 1,3 cm dikke sectie tot ongeveer 10 minuten. Opmerking: de tijd is afhankelijk van de dikte van de mal.

Het toevoegen van een geschikte hoeveelheid Plat-Cat™ uithardingsversneller zal ook de ontvormtijd verkorten. De verwerkingstijd en uithardingstijden kunnen worden verlengd met Slo-Jo™ uithardingsvertrager. Hard rubber niet uit bij een temperatuur lager dan 18°C.

Vormprestaties en opslag - De fysieke levensduur van de vorm hangt af van hoe u deze gebruikt (gegoten materialen, frequentie, enz.). Het gieten van schurende materialen kan de details van de mal snel verslechteren, terwijl het gieten van niet-schurende materialen (was) geen invloed heeft op de details van de mal. Voordat u de mal opbergt, moet deze worden schoongemaakt met een zeepoplossing en volledig worden drooggeveegd. Tweedelige (of meer) mallen moeten worden geassembleerd. Mallen moeten op een vlakke ondergrond in een koele, droge omgeving worden bewaard.

Benodigdheden

- Mengbekers

- Maatcylinders & bekers

- Weegapparatuur

- Kwasten

- Veiligheidsmaterialen

- Losmiddellen

Mengen, Meten & Wegen

Kwasten

Bescherming

Losmiddelen

Hier vindt u onze produkten gerangschikt naar diverse toepassingsmogelijkheden, zoals: Lifecasting, boetseren, afvormen, gieten, make-up, stuntwerk, dentaalwerk en studie.